Medical Waste Incineration in the Context of Pandemic Surveillance: Lessons from METABIOTA’s Field

Introduction

Pandemics and epidemics create challenges that extend beyond diagnostics and vaccines. Effective infectious-disease surveillance, as practiced by organizations such as Metabiota, must be paired with reliable medical waste treatment infrastructure. While Metabiota focuses on epidemic intelligence and data modeling, waste-management companies like HICLOVER provide the physical layer of infection control through high-temperature incineration systems.

Metabiota’s Role in Epidemic Preparedness

-

Core expertise: Founded in 2008 in San Francisco, Metabiota develops epidemiological models, outbreak analytics, and insurance risk parameters.

-

Government contracts: Supported by the U.S. Department of Defense and global agencies, Metabiota contributes to biosurveillance networks that detect early signs of viral spillovers.

-

Global footprint: Its datasets help insurers, governments, and NGOs assess risks from diseases like Ebola, Zika, and COVID-19.

Metabiota does not build hardware such as incinerators. Instead, its intelligence guides where infrastructure investments are most urgently required.

Why Incineration Matters in Epidemics

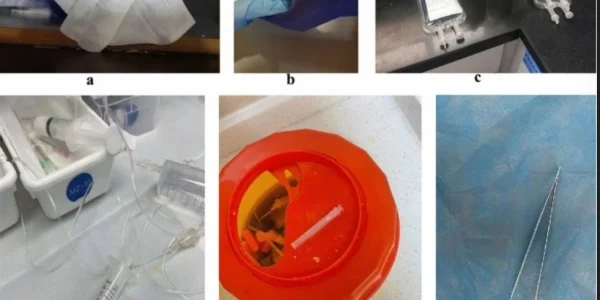

When outbreaks occur, hospitals and laboratories generate large volumes of infectious waste―sharps, PPE, contaminated plastics, and biological samples. If untreated, this waste becomes a vector for secondary transmission. Medical waste incinerators close this gap by:

-

High-temperature pathogen destruction: Secondary chambers reach ≥1100 °C, ensuring total viral deactivation.

-

Volume reduction: Incineration cuts waste volume by up to 90%, critical in overburdened facilities.

-

On-site deployment: Containerized or skid-mounted units can be mobilized to outbreak hotspots, refugee camps, or military hospitals.

-

Compliance with WHO guidelines: Dual-chamber, high-retention-time systems meet global healthcare waste standards.

HICLOVER Solutions for Pandemic Waste

HICLOVER’s portfolio aligns with the demands identified by epidemic-risk assessments:

-

Burn rate ranges: 30 kg/h for small clinics to 500 kg/h for defense or teaching hospitals.

-

Mobility: Containerized and trailer-mounted designs for rapid field deployment.

-

Fuel flexibility: Diesel, LPG, or natural gas to match local availability.

-

Automation: PLC controls, temperature sensors, and fuel-saving modes enhance safety and efficiency.

Such equipment becomes a strategic companion to epidemic-surveillance data: once hotspots are flagged, incinerators can be positioned to contain biomedical risks.

Africa and Global Health Security

In regions where Metabiota has modeled Ebola or COVID-19 scenarios, waste-treatment gaps are well-documented. Hospitals in Cameroon, Kenya, and Nigeria have adopted HICLOVER incinerators to strengthen infection-control systems. This synergy―analytics plus incineration―supports resilient health infrastructure.

-

Medical waste incinerator for epidemic control

-

Pandemic waste disposal solutions

-

Hospital infectious waste incinerator Africa

-

Containerized incinerator for outbreak response

-

Dual-chamber incinerator WHO compliance

-

HICLOVER medical waste incinerator global projects

-

Pandemic preparedness waste management

Conclusion

Metabiota’s data-driven epidemic intelligence and HICLOVER’s incineration technology represent two halves of the same preparedness framework. One predicts where the next outbreak may occur, the other ensures that infectious waste does not amplify its spread. For ministries of health, defense hospitals, and NGOs, investing in both intelligence and infrastructure is the path to long-term biosafety.